Aviation Acoustic Solutions

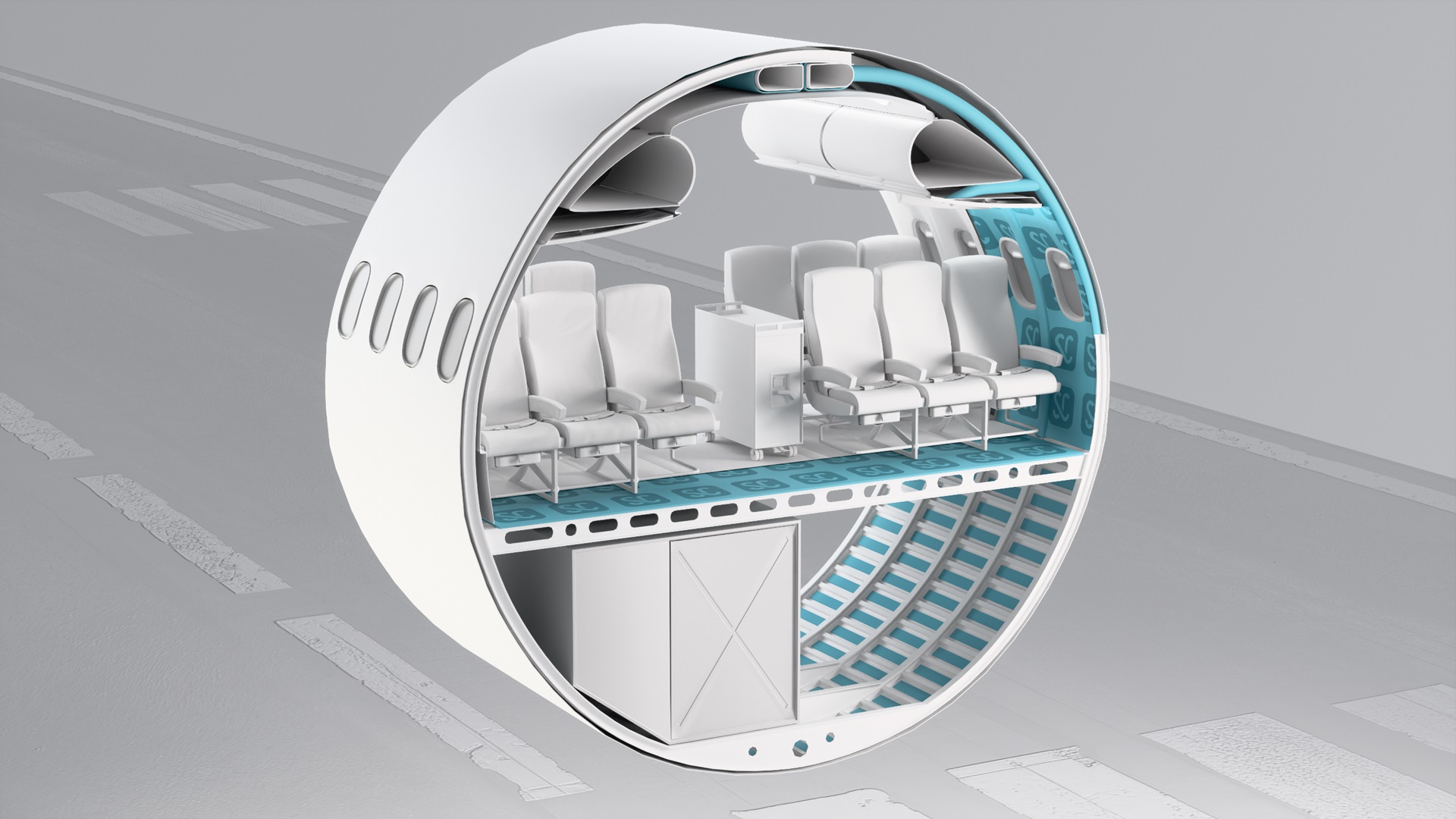

Aircraft encounter a myriad of unique noise, vibration, temperature and moisture challenges, including the thunderous roar of engines during takeoff and landing, the disruptive effects of aerodynamic turbulence throughout flight, the persistent vibrations caused by engine and airframe operations, and the condensation that occurs during temperature changes.

Enhanced operation, dependability, and excellence

Engines and other electro-mechanical components, air turbulence during flight and onboard environmental control systems (ECS) all impact the operation and comfort of passengers. Strict quality standards that govern the aviation industry require aircraft suppliers to adhere to rigorous manufacturing and test standards to ensure the safety and comfort of passengers and crew.

Protect from environmental challenges

Commercial and military aircraft encounter demanding thermal conditions when at high altitudes or at the gate and during extreme weather conditions. For instance, the intense heat generated by jet engines and the frigid temperatures at cruising altitudes pose significant challenges in maintaining both aircraft performance and passenger comfort.

Acoustic solutions from the inside out for aviation

Meeting strict aviation standards requires advanced engineering solutions, proven materials, meticulous testing plans, and adherence to strict quality standards to ensure the stability proper performance of aircraft. We deliver on these with our proven portfolio of advanced engineering services, diverse product offering and adherence to strict quality standards including ISO 9001:2015 and AS9100:2016 registration.