Uniseal vs. Matte Film: What’s the Difference and When to Use Each?

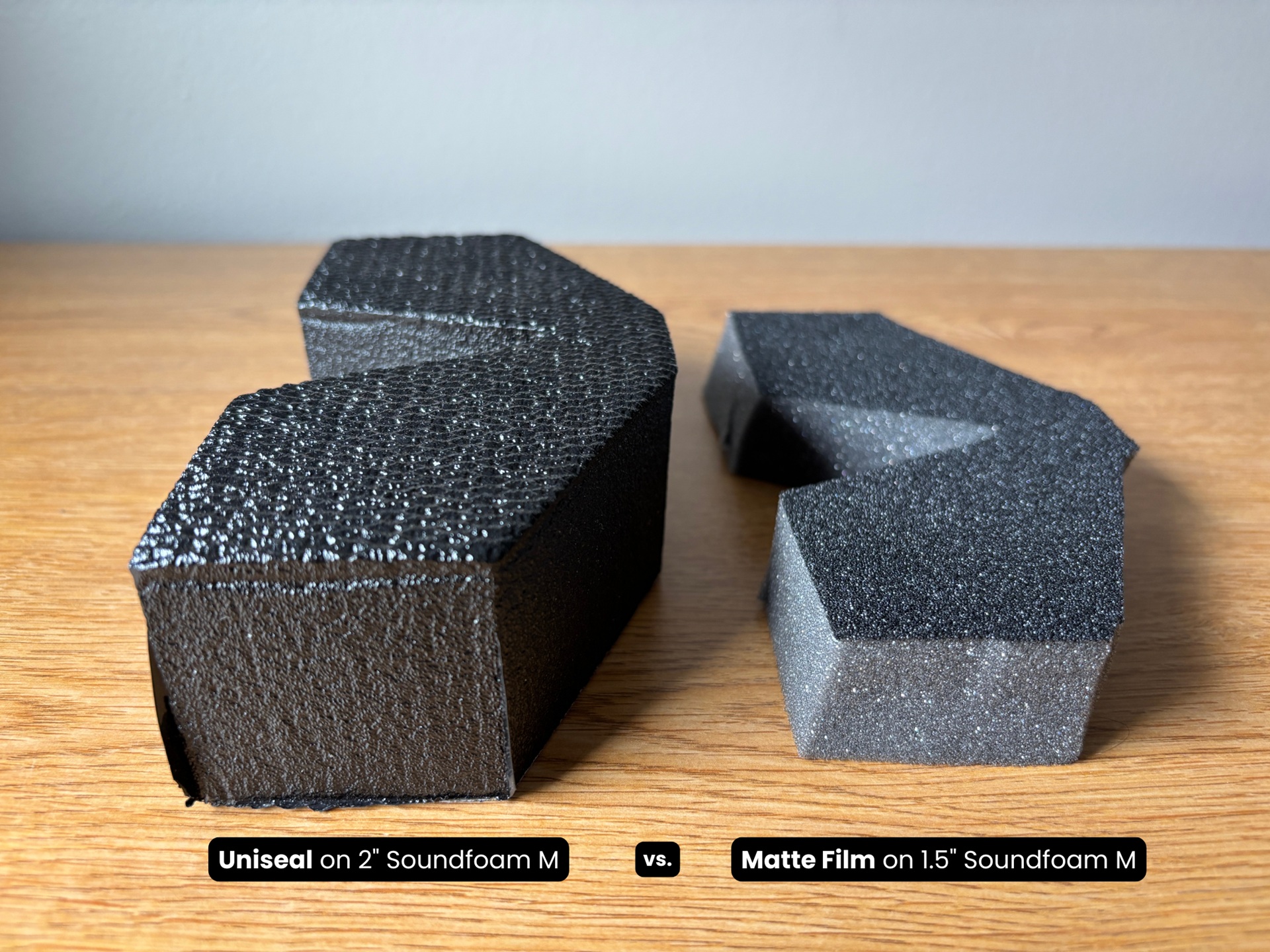

In the world of acoustic materials, questions about product specifications and application methods are common—and important. At Soundcoat, two of the most frequently asked about solutions are matte film (also known as urethane film) and Uniseal (also known as edge sealing). While they may appear similar at first glance, these solutions serve different purposes, perform differently in various environments, and are manufactured using different processes. This article will break down the distinctions between matte film and Uniseal, explain when to use each, and clarify why requesting cut samples of Uniseal is counterproductive.

What Is Matte Film?

Matte film is a type of urethane facing used to enhance the surface properties of acoustic foam. It offers:

- A clean, professional look

- Low reflectivity, making it ideal for visual-sensitive environments

- Improved durability in handling and exposure to mild environmental factors

- Minimal impact on acoustic performance, maintaining sound absorption characteristics of the base foam material

Matte film is typically laminated onto acoustic foam products as a protective facing. It's chosen for applications where aesthetics or surface protection are important. You can find matte film used across industries like aerospace, medical, and electronics where both function and cleanliness are critical.

What Is Uniseal?

Uniseal is not just a material—it’s both a product and a process. Uniseal combines Soundcoat’s high-performance Soundfoam (open-cell acoustic foam) with a vacuum-laminated urethane film, applied to all exposed foam surfaces except the backside, which is typically mounted to a surface.

What makes Uniseal unique?

- Vacuum lamination process ensures complete, seamless coverage of exposed foam surfaces

- Cut to exact customer specifications before lamination, meaning the product is created to fit your application precisely

- No seams or exposed edges—this is critical for fluid resistance and environmental sealing

- Not intended for post-processing—cutting Uniseal after lamination would break the seal and expose the foam, compromising its integrity

Key Differences: Matte Film vs. Uniseal

When Should You Use Matte Film?

Choose matte film when:

- You need cleanable, low-gloss finishes for exposed acoustic foam

- The application doesn’t involve harsh environments or fluid exposure

- You’re working in controlled environments

- You require flexibility in part shapes and quantities (sheets can be cut as needed)

Matte film is ideal for moderate-protection needs and environments where clean aesthetics and controlled particle shedding are important, but seamless sealing isn’t critical.

When Should You Use Uniseal?

Choose Uniseal when:

- The part will be exposed to fluids, moisture, or contamination risks

- You need environmental protection for the foam itself, particularly at the edges

- You want a fully sealed solution that won’t degrade from external conditions

Uniseal is the go-to solution for demanding applications such as aerospace duct liners, medical enclosures, and semiconductor equipment, where maintaining cleanliness and preventing fluid ingress are essential.

Why Can’t You Get a Sample of Uniseal?

This is one of the most common questions we get: “Can I get a sample of Uniseal to cut and test?” Unfortunately, the answer is no—and here’s why:

Because Uniseal is created using a vacuum lamination process after the foam is custom cut, the seal is applied only after the part is shaped. If you were to cut into a Uniseal-covered sheet or part, the cut edges would be exposed, defeating the purpose of environmental sealing. The moment the foam is cut post-lamination, it’s no longer Uniseal—it's just foam with matte film on it.

If you're evaluating Uniseal for a project, we can provide generic, but fully finished samples pieces, allowing you to assess both form and function before beginning a fully-customized order built to your specifications.

Final Thoughts

Choosing between matte film and Uniseal comes down to understanding the specific requirements of your application—environmental exposure, cleanliness, aesthetics, and acoustic performance all play a role. While matte film is a versatile and economical choice for many low-impact environments, Uniseal offers a more robust, sealed solution for high-demand conditions.

If you’re unsure which option is right for you, our engineering team is happy to help evaluate your needs and recommend the best path forward.

Interested in learning more?

Explore our Matte Film page, learn about our high-touch finishing capabilities like Uniseal or hydrophobation, or fill out our Contact form to request samples of either product.