Commercial Construction Acoustic Solutions

During the planning stage of new industrial construction projects, or during the retrofit of existing spaces, it is essential to address various challenges related to noise and structure-borne vibration. Doing so will ensure an optimum acoustical environment to promote worker safety and comfort resulting in improved productivity.

Improve functionality of buildings

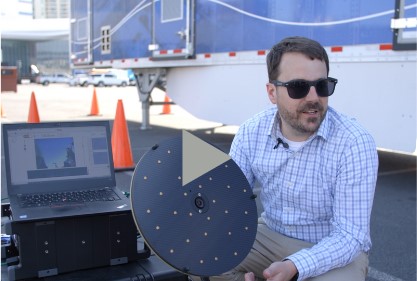

Reverberative noise and sound transmission within the structure can negatively impact the usability of the adjoining spaces. For example, meeting rooms, offices, break rooms, etc. can all be affected by unwanted noise. The Soundcoat 360 methodology of onsite testing, predictive analysis and modeling, and validation can be performed to create solutions to address these issues.

Optimize indoor conditions

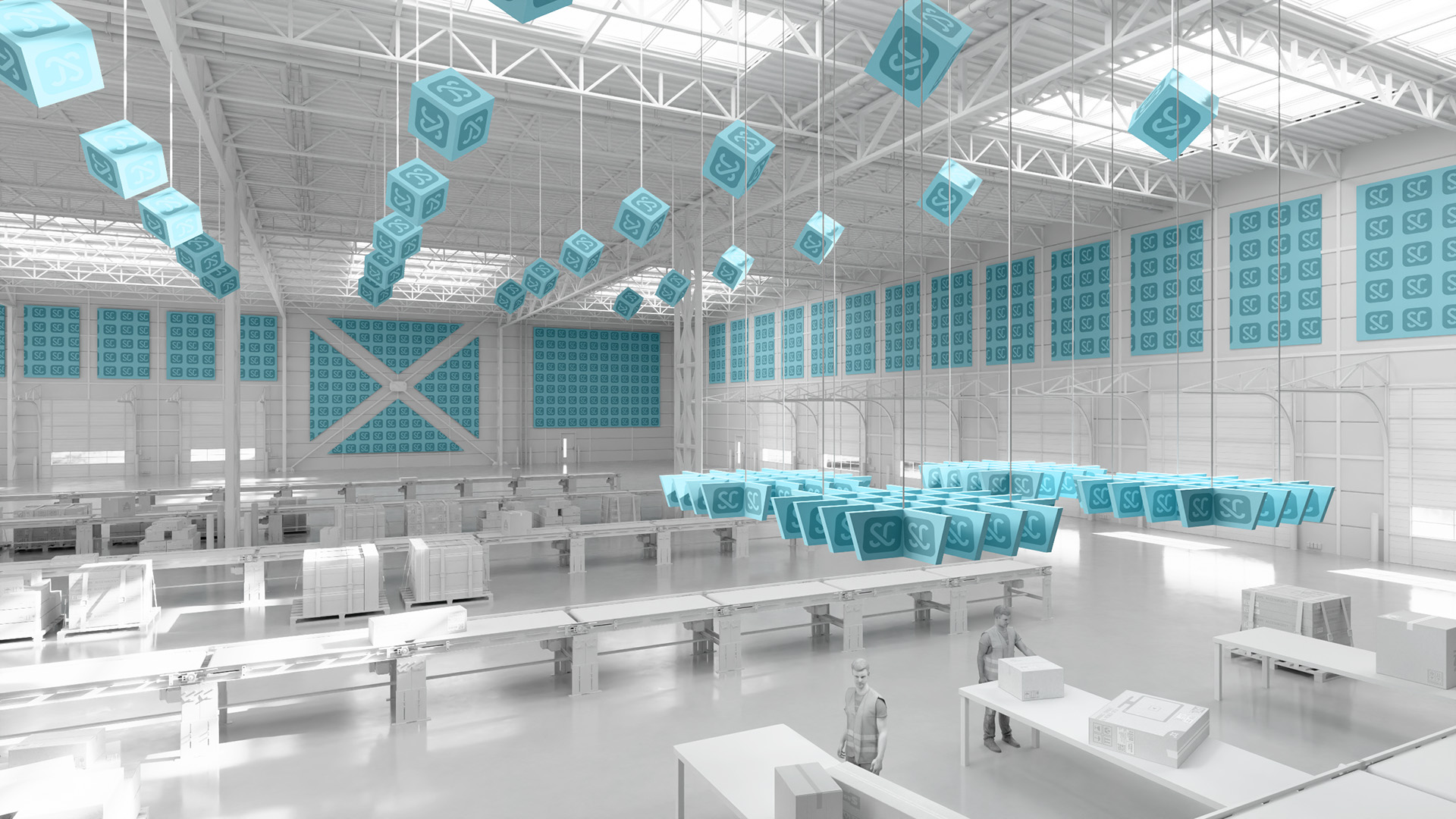

Industrial buildings are impacted by a number of disruptive noise sources created by electro-mechanical systems. These sources include conveyors, automation equipment and material handling systems, power generating and energy storage equipment, HVAC systems, server racks and electrical devices, and other industrial manufacturing equipment. Through a holistic approach of addressing the noise sources as well as the space, Soundcoat can help create a better workplace environment.

Acoustic solutions from the inside out for commercial construction

What if you could predict how noisy a space will be – even before your designs are finished – and engineer solutions into the plan? With the proprietary Soundcoat 360 Solution™ you can do just that.