Revolutionizing Engineered Acoustics

We started with a bold question, “How can we radically simplify our customers’ design process when it comes to acoustic performance?” The answer was equally bold, “Transform the way acoustics is approached—from the inside out.”

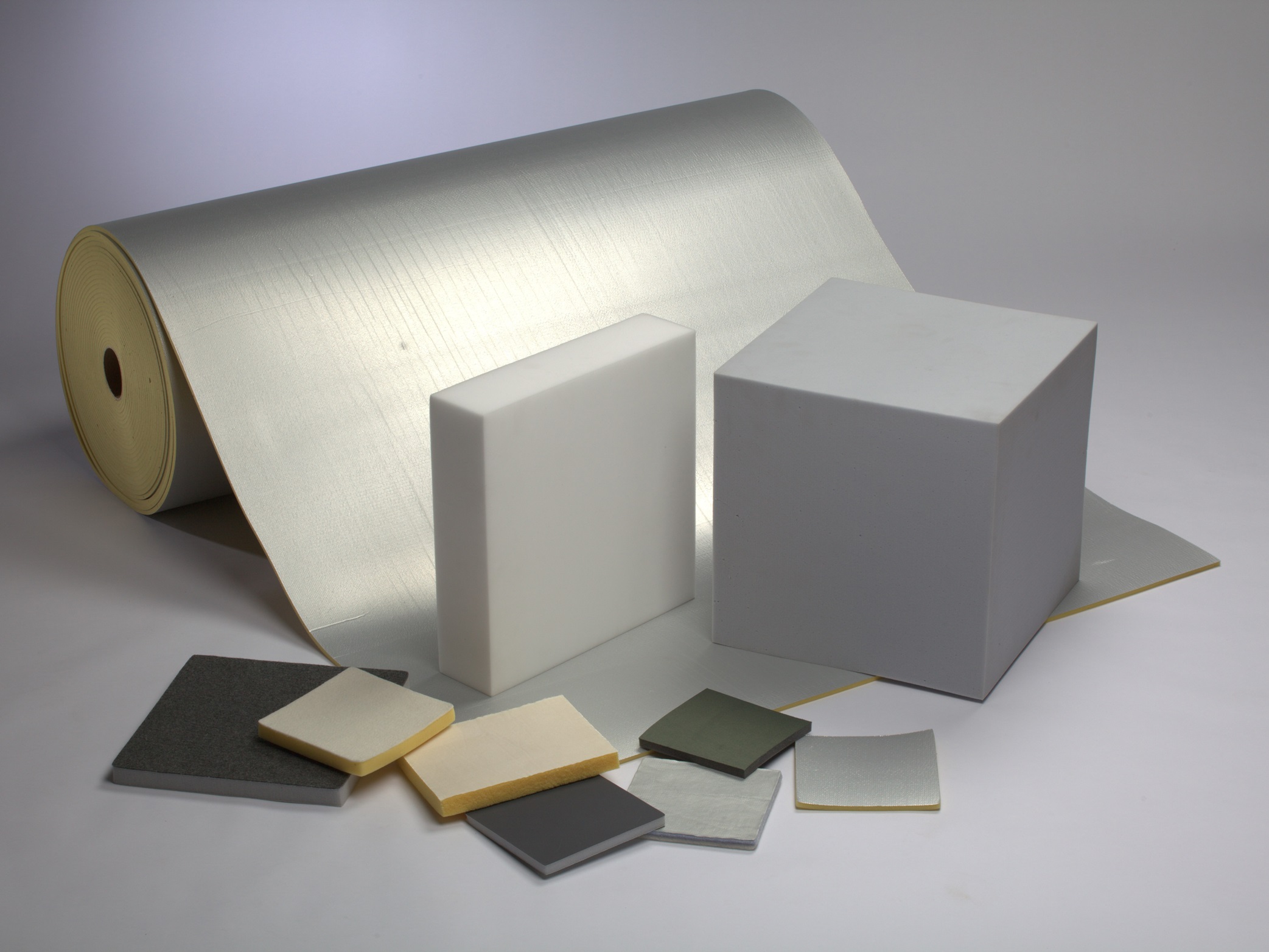

By investing in the right people, processes, and platforms, we developed Soundcoat 360 Solution™; a proprietary process that combines testing, acoustic modeling, and predictive analysis to develop specialized engineered acoustic solutions for industrial spaces and OEM products—before anything is ever built.

The Soundcoat 360 SolutionTM is your design team’s tactical advantage to:

- Optimize your product design process

- Expedite products to market

- Improve sound quality of spaces and products, while minimizing design costs

The Soundcoat 360 SolutionTM is a unique differentiator for us. In an increasingly noisy world, we want to offer our customers a quieter choice in the EV charging industry, and Soundcoat has been our key partner in finding effective solutions.

Pioneer E-Boost Mobility

Future of acoustic engineering today

Soundcoat 360 Solution™ is transforming the way acoustics is approach – from the inside out.