Semiconductor OEM Acoustic Mitigation Solutions

Semiconductor equipment manufacturing entities face exacting standards and demands for continual quality improvement. From the manufacturing equipment itself to the building and spaces the equipment occupies, Soundcoat’s suite of acoustics solutions offer precise mitigation solutions to help semiconductor OEMs meet and exceed quality standards.

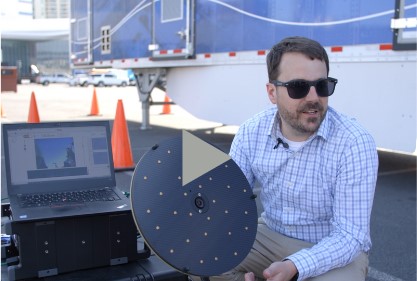

Improve metrological tool operation

Semiconductor metrology tools are sensitive to airborne acoustics that can alter precision positioning of test instruments and contribute to false readings of ongoing test procedures. Soundcoat can facilitate better metrological tool operation by providing acoustic materials that block, absorb and dampen external sources of unwanted noise and vibration contamination.

Isolate thermal contamination

Unmitigated heat during semiconductor processing can negatively impact the quality of the products, longevity of equipment, and health and safety of operators. Soundcoat has materials and engineering solutions to mitigate these sources of thermal contamination.

Reduce ambient noise to improve worker safety

Environmental conditions in certain semiconductor fabs require operation by people who can be negatively affected by the mechanical noise of both the machines and the general facility operations such as its HVAC, onsite server rooms, and back-up power generation. Soundcoat can offer solutions to lower the noise threshold across all of these environments. Whether you are in the early design phases, or retrofitting an existing facility, Soundcoat has the solutions to help.

Acoustic solutions from the inside out for semiconductor OEM

Through our diverse product catalog, testing capabilities, and advanced acoustic engineering services, Soundcoat can help ensure the accuracy of semiconductor metrology tools, enable thermal isolation to extend equipment lifespan, and assist in tool development to optimize sound, while meeting industrial and human safety standards.