Medical OEM Noise and vibration

Noise and vibrations resulting from the operation of compressors, pumps and fans are incredibly problematic when seeking a comfortable ambient environment where these devices typically operate. The placement of these individual components within the equipment, isolating the components and then acoustically treating the area are all critical factors in achieving design goals. Lining the interior walls with acoustic materials, creation of molded casings, or even full molded acoustic housings that can provide both sound absorption and sound transmission loss, are all ways to address noise attenuation in the design. In the medical OEM market, addressing noise and vibration challenges associated with medical devices is crucial to ensuring optimal product performance and improving patient comfort.

Component noise control

Fans are often used in medical equipment to cool the electronic components within the device. The fan mounting method, its location within the device, and the airflow path are all important to consider for noise attenuation. These issues can be addressed with proper isolation of the fan, as well as creating molded acoustical ducts to address the fan intake and exhaust airflow. Similarly, other noise-generating components such as compressors and pumps need to be addressed. Foam molded parts, or 2D composites incorporating foam-damping or foam-barrier materials, are often solutions for noise attenuation of these components.

Improve user comfort

Hospital and in-home medical devices are essential for managing various health conditions but often produce audible noise during operation, which can disrupt patients' overall comfort. Additionally, noisy lab and testing equipment can have a negative impact on the medical professionals working in these environments. Care must be taken by OEMs to ensure their products are quiet by design.

Acoustic solutions from the inside out for medical OEM

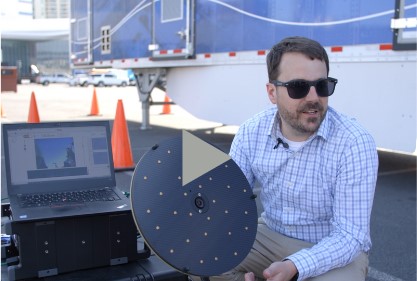

Our proprietary Soundcoat 360 Solution™ can address all these concerns through discovery, testing, predictive analysis, modeling, implementation of products and validation.